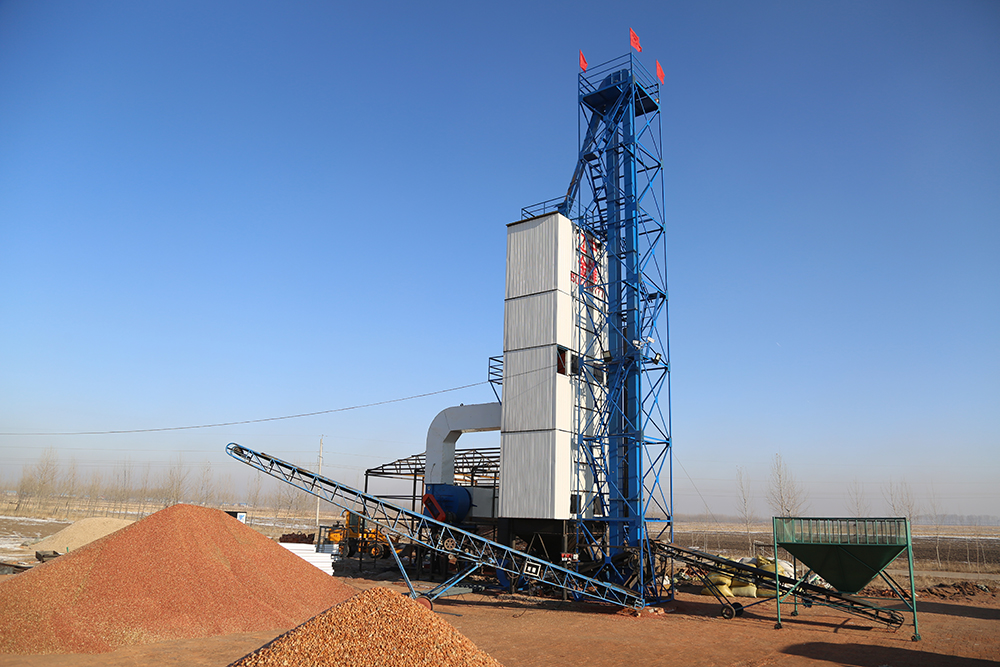

Diesel Gas Burner Tower Grain Dryer

Product Description

Diesel Gas Burner Tower Grain Dryer

1. This rice paddy dryer With low noise centrifugal and overload protection fan, startup mode is slowly, the supply air is uniformly and service life is long.This rice drying tower is mainly used for drying grain. Drying grain belongs to continuous work. It has higher requirements on the stability and continuous operation of the dryer during use. The material requirements for the material selection and wear parts of the dryer are very high. The batch type circulating dryer produced by our factory belongs to the low-temperature energy-saving drying equipment. It has the characteristics of convenient installation, simple operation, low noise, low energy consumption and low power. It mainly dries high-quality grain and meets user needs.

Application:

Rice, wheat, barley, buckwheat, barley, corn, soybean, mung bean, broad bean, red bean, black bean, sorghum, millet, rapeseed, sunflower seed, etc.

Features

1. High height drying layer. The drying layer is 2.7 meters high, 1.3 meters higher than other type grain drying equipment,the drying output is large and the effect is good.

2. Stainless steel internal material. Our grain dryer internal material is made of 316 stainless steel, which is clean and has a long service life.

3. Painted body. The grain dryer uses the electrostatic spray coating paint process, which has the characteristics of heat resistance, wear resistance and corrosion resistance.

4. Simple operation. It takes more than 4 people to work when operating other types of grain dryers; our grain dryers only need one person to work.

5. Drying effect is good. When drying the grain, the drying effect is ensured to be uniform, and the grain breaking rate is low, and the wheat fiber structure is not damaged when the wheat is dried.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Grain Dryer Technical Parameter Table

| project

model | corn |

Rice

| Installed capacity(KW) | Hot stove ( 10'kcalh) | ||||

| Daily processing capacity T/D | Tax reduction% | Hot air temperature ℃ | Daily processing capacity T/D | Tax reduction% | Hot air temperature ℃ | |||

| SNH-5 | 100 | 10-15 | 120-150 | 200 | 2-3 | ≤50 | 41.35-63.25 | 120 |

| SNH-7.5 | 150 | 10-15 | 120-150 | 300 | 2-3 | ≤50 | 62.55-82.75 | 180 |

| SNH-10 | 200 | 10-15 | 120-150 | 350 | 2-3 | ≤50 | 81.95-106.25 | 240 |

| SNH-15 | 300 | 10-15 | 120-150 | 550 | 2-3 | ≤50 | 106.25-143.45 | 360 |

| SNH-20 | 400 | 10-15 | 120-150 | 700 | 2-3 | ≤50 | 193.4-203.4 | 480 |

| SNH-25 | 500 | 10-15 | 120-150 | 800 | 2-3 | ≤50 | 240.9-251.9 | 600 |

| SNH-30 | 600 | 10-15 | 120-150 | 1000 | 2-3 | ≤50 | 272.8 | 720 |

| SNH-40 | 800 | 10-15 | 120-150 | 1300 | 2-3 | ≤50 | 406.8 | 960 |

| SNH-50 | 1000 | 10-15 | 120-150 | 1800 | 2-3 | ≤50 | 508.4 | 1200 |

After-sales Commitment

★ We have complete customer files for our products, and provide technical guidance and Accessories supply for life.

★ Dryer complete sets of equipment, within a drying period, such as the manufacturer's quality reasons to provide "three guarantees" service.

★ Respond to customer's use failure within 4 hours and provide initial solution.

★ After-sales service phone is turned on 24 hours a day to provide you with feedback on technical quality and problem reasons.

★ Respond within 48 hours to provide door-to-door service upon request of the user (the time will increase or decrease due to the distance of the area)

Jinfeng Drying Equipment Co., Ltd. of Qinghe District, Tieling City, Liaoning Province, is a professional manufacturer mainly manufacturing grain drying equipment and electronic truck scales. The company has more than 180 employees, including 76 engineering and technical personnel. The company has a high-quality production and manufacturing team, product research and development team, marketing and sales team, and enterprise management team. It has advanced production lines and testing methods to provide new products for the majority of users. High-quality services such as development and design, equipment manufacturing, installation, debugging and maintenance.

For many years, our company has insisted on "survive by quality, promote development by credibility", adopts the advanced technology of "low temperature drying", has developed three series of cross flow, forward and backward flow and mixed flow, and more than ten varieties of grain Dryer, RFL series coal-fired hot blast stove, DTJ series low crushing bucket elevator, drum-type primary cleaning screen, grain conveyor series products and power distribution system, the complete set of equipment are independently developed, designed and manufactured by our company. According to customer needs, automatic temperature control, automatic control of material level and fault safety protection devices can also be added. The product is suitable for drying grains such as corn, rice, wheat and soybeans and drying other granular materials such as cotton.

The SCS-10-150 series truck scales and quantitative packing scales produced by our company have superior performance, high precision and good stability.

Our company adheres to the business philosophy of "quality assurance, customer first", with high-quality products, reasonable prices and perfect after-sales service, we sincerely welcome the presence of our friends!

Product Categories : Tower Grain Dryer > Rice Drying Tower